It is important to carefully arrange the stowage of packaged cargo, such as cartons, cases and drums, in order to maximize the use of available space. This will effectively maximize freight capacity while helping to prevent cargo from shifting during transportation. Finally, in order to avoid cargo displacement and other subsequent damage, which can be caused by external factors during transport, it is essential to secure cargo within the container. Certain normal methods of stowage and securing are explained below.

Carton

The photo on the right shows a completely stuffed container. Securing is unnecessary.

When a container is packed right from the beginning with packages suited to its size, it is possible to completely use up the space within the container.

And when no additional securing materials are needed, that means cost savings.

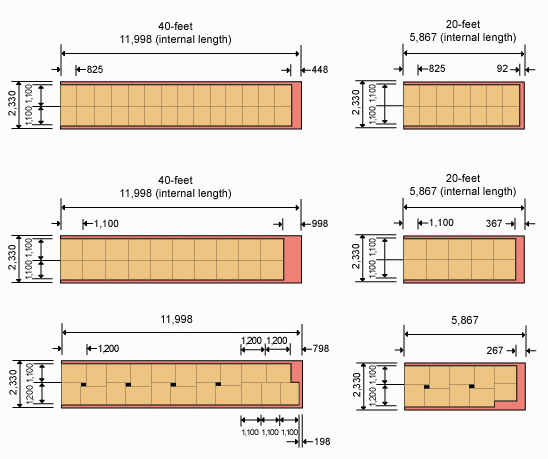

Palletized Cargo

The loading of cargo, traditionally performed manually, has been expedited by the use of pallets and forklifts.

Moreover, compared to manually loaded cargo, the palletized form is more likely to prevent displacement or damage.

To maximize space, it is imperative to utilize pallets that can be loaded into containers without leaving unfilled space.

Air Bag

It’s the best way to fill narrow, difficult spaces to secure cargoes, and it’s simple to use.

First insert the empty Air Bag into the space, then feed in pressurized air, inflating the bag until it comes in contact with the cargo.

Drums

As a rule, drums are stowed vertically with the bungholes facing upwards. Since the contents of drums are mostly liquids or powders, it is essential to conduct thorough pre-loading inspections.

When drums are stowed in layers, it is necessary to construct plywood flooring for each layer. When the container is filled with drums to the doorway, a pallet can be placed between the door and the drums to eliminate gaps.

Alternatively, dunnage can be used to achieve a chocking function (using a wooden detainment device to prevent the movement of the cargo). When the drums do not fill the container to the doorway, they must be lashed with ring rope to the sidewall rings and chocked thereafter with a pallet or dunnage.

Reefer as Dry

Depending on sea routes, it is possible to use reefer containers, without the refrigeration unit engaged, as dry containers. In this case, loadable capacity will be smaller than normal dry container due to the generator/insulating material, and securing methods will be limited. However, thanks to the insulating material, change of inside temperature can be moderated.

Unpacked Machinery

When planning stowage, it is necessary to carefully consider cargo handling and lashing methods in line with the shape of the cargo.

Cargo weight must be restrained with lashing after loading. It is necessary to carefully choose an anchor for the lashing that is strong enough to hold the cargo and at the same time will not damage the cargo.

UPC (Unpacked Cars)

In general, when automobiles are loaded, ropes are used to form a four point lashing from lashing rings. A vehicle-chocking device is used to secure the wheels.

Sufficient room must be left between the sides of the container and the vehicle to facilitate maneuvering in the container.

Generally, the transport of vehicles is limited to passenger-sized automobiles, with construction equipment and other large vehicles moving via break bulk or on flat rack containers.